Twill Weave Wire Mesh – AHT Hatong

Introduction

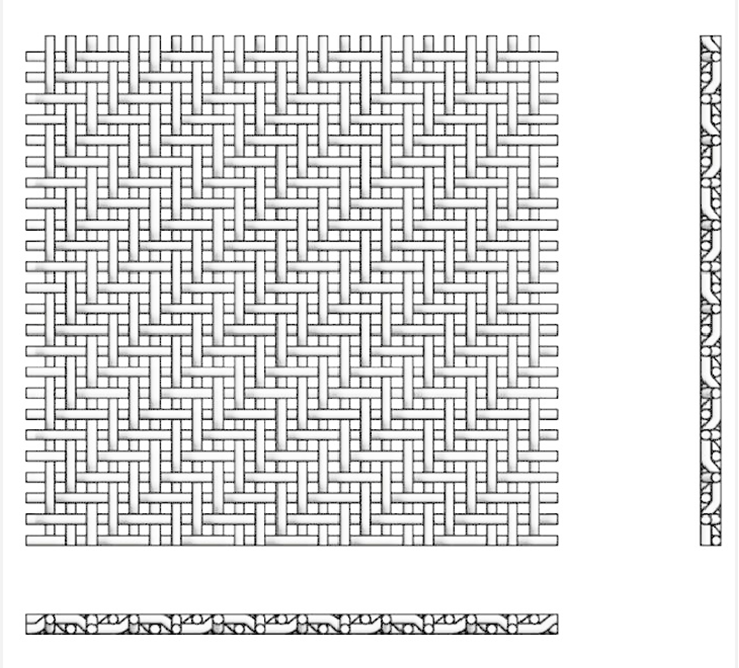

Twill weave wire mesh is produced by passing each weft wire alternately over and under two warp wires. The pattern is staggered on successive warp wires, giving the appearance of parallel diagonal lines.

This weave allows the use of proportionately heavier wires in a particular mesh count (number of openings per lineal inch) than is possible in plain weave.

This cloth has a wide application capable of supporting greater loads and finer filtration.

Display

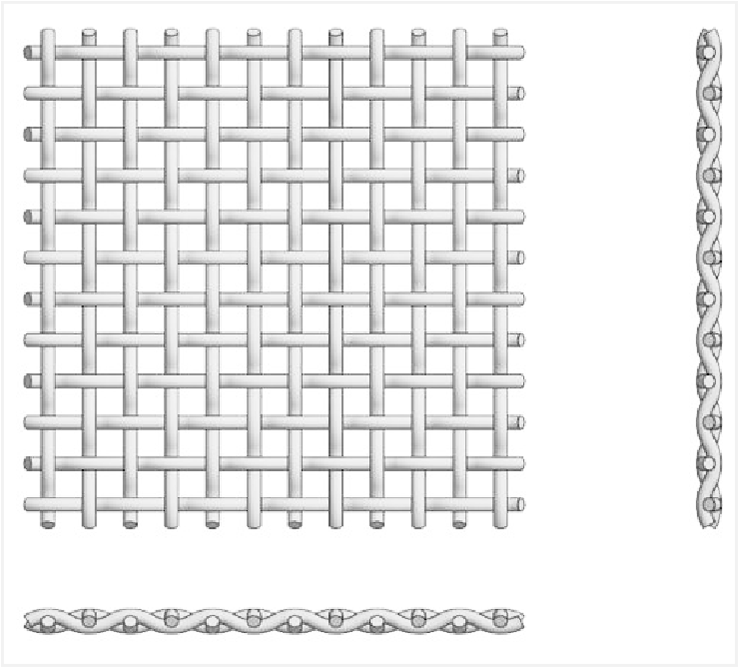

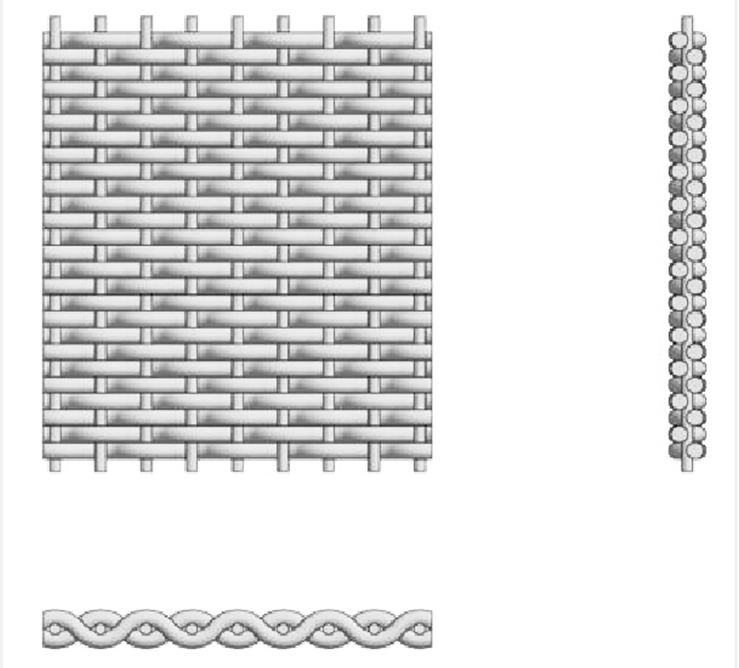

Plain Weave Wire Mesh

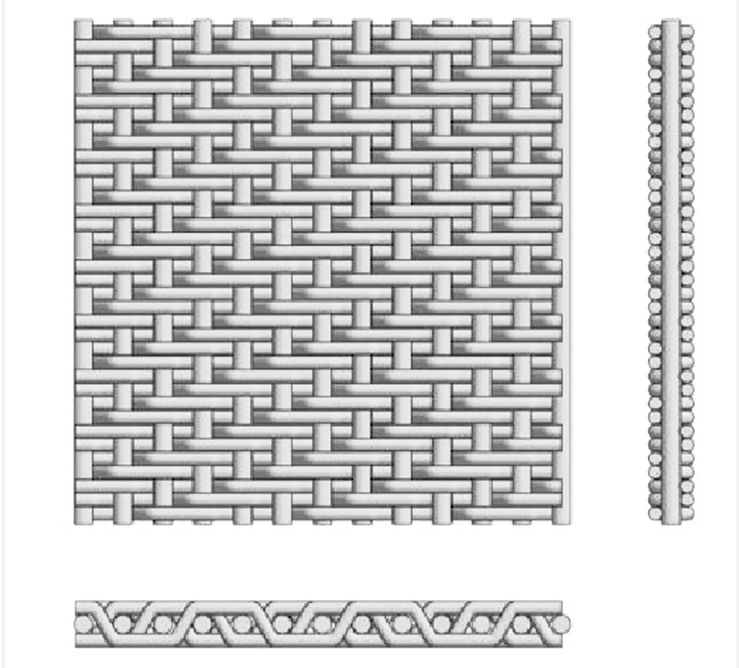

Twill Weave Wire Mesh

Five-Heddle Weave Mesh

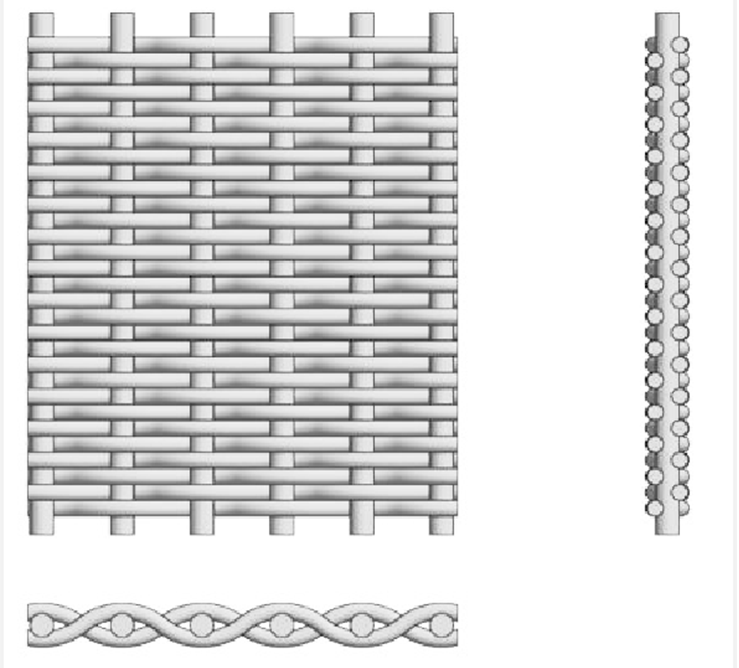

Dutch Plain Weave Wire Mesh

Dutch Twill Weave Wire Mesh

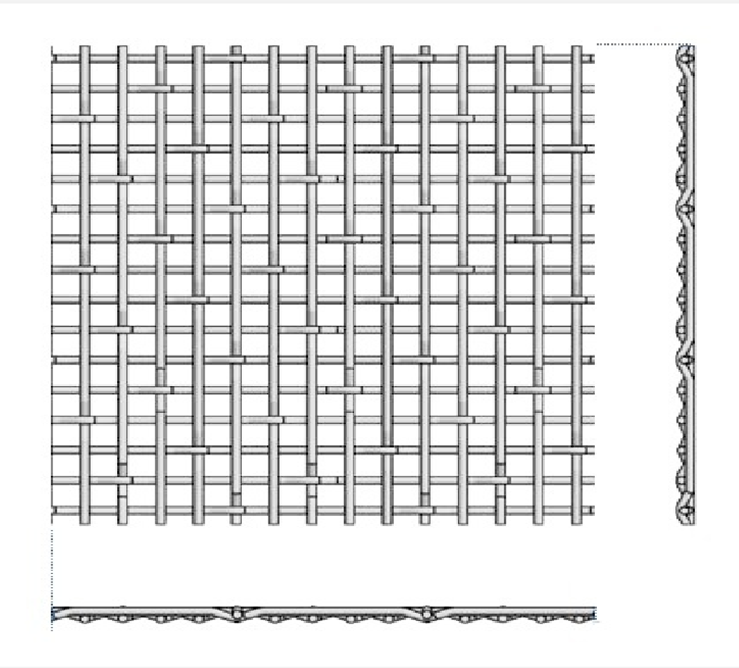

Reverse Dutch Wire Mesh

Specification

Common Specification

Wire diameter: 0.025mm to 2.0mm

Mesh: 10 to 400 mesh

Width: 0.5m ---- 6m

Length: 10m to 100m

| Mesh Count per Inch | Wire Diameter mm | Aperture Size mm | Open Area | Weight for Stainless Steel (kg/sq m) |

| 230 | 0.036 | 0.074 | 45% | 0.15 |

| 250 | 0.04 | 0.062 | 37% | 0.2 |

| 270 | 0.04 | 0.054 | 33% | 0.21 |

| 270 | 0.036 | 0.058 | 38% | 0.17 |

| 300* | 0.04 | 0.045 | 28% | 0.24 |

| 300* | 0.036 | 0.055 | 42% | 0.13 |

| 325* | 0.036 | 0.042 | 29% | 0.21 |

| 325 | 0.028 | 0.05 | 41% | 0.13 |

| 350* | 0.03 | 0.043 | 34% | 0.16 |

| 400* | 0.03 | 0.034 | 27% | 0.18 |

| 500* | 0.025 | 0.026 | 26% | 0.16 |

Characteristic

Precise structure, uniform mesh, good filtration accuracy, wear resistance, high temperature resistance, strong acid resistance, corrosion resistance

Application

Twill weave wire mesh is a versatile and durable material that can be used for a variety of different applications. Due to its high tensile strength, corrosion resistance, and temperature resistance. It is commonly used in industries of automotive, aerospace, chemical, and food processing etc, for the filtration, Separation, Reinforcement, Protection.